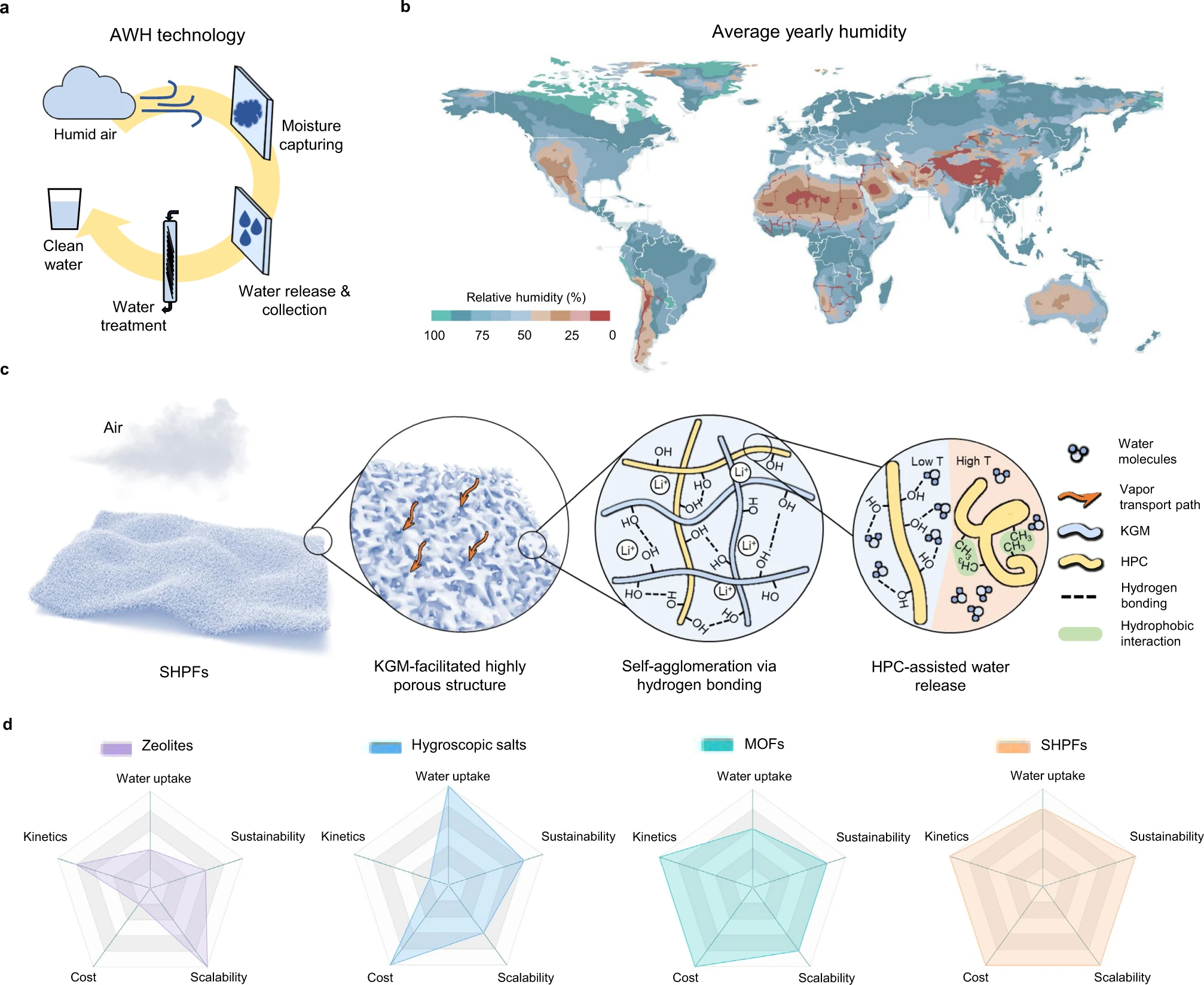

Water shortage is a major problem facing most of the world's population, but as long as appropriate equipment is available, drinking water can be extracted from the air Researchers at the University of Texas at Austin have now demonstrated a low-cost gel film that can even extract drinking water from very dry air every day

This gel is composed of two cheap and common main ingredients - cellulose from plant cell wall and konjac gum, a widely used food additive. These two components work together on the gel film, which can absorb water from the air and release it as needed without a lot of energy.

First, the porous structure of konjac gum attracts water to condense from the air around it. At the same time, cellulose is designed to react to mild heat, become hydrophobic and release captured water.

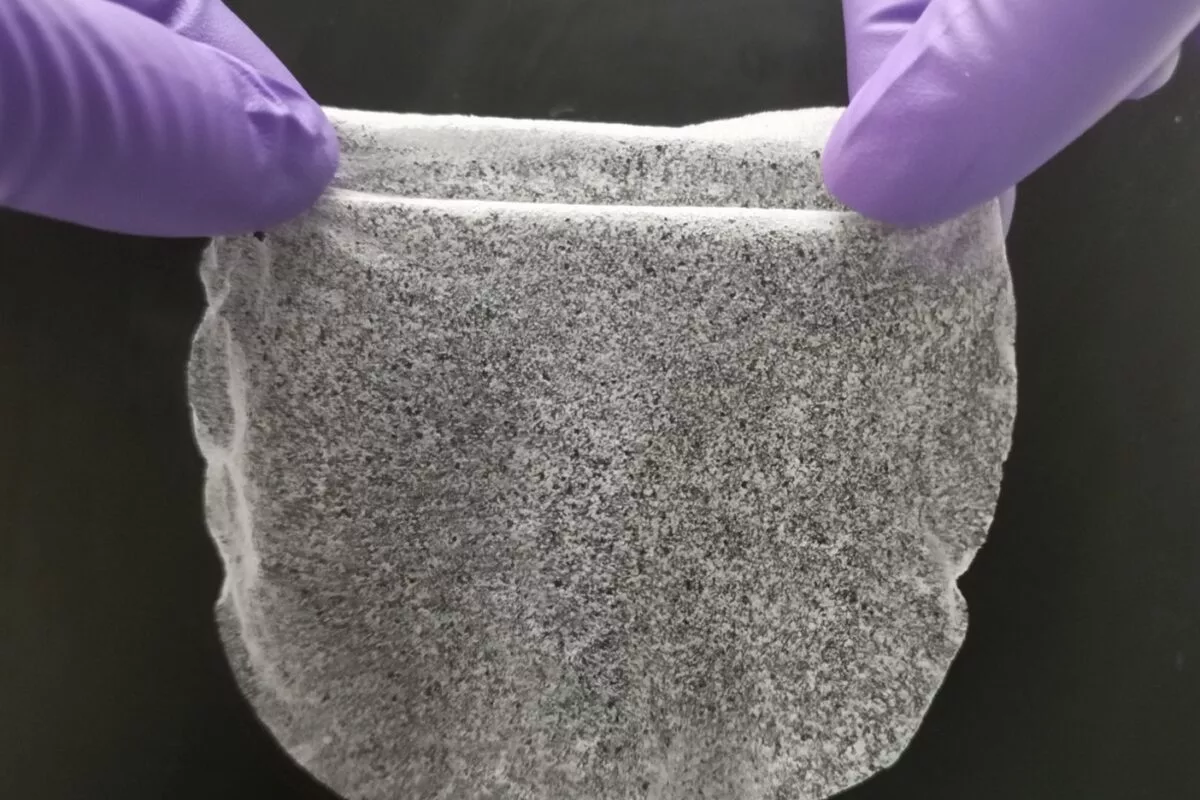

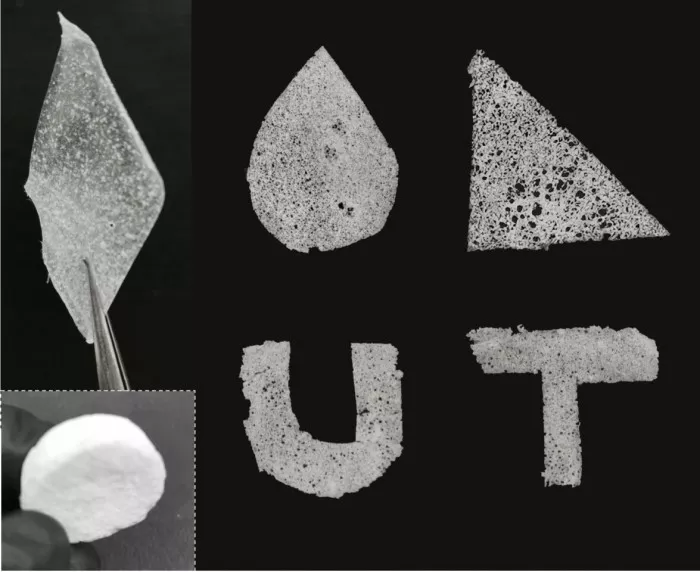

The team said that making this gel is also quite simple. The basic ingredients are mixed together and then poured into a mold where they can solidify in two minutes. After that, it is freeze-dried, then stripped from the mold and ready to work. It can be basically made into any desired shape and can be scaled up quite easily at low cost.

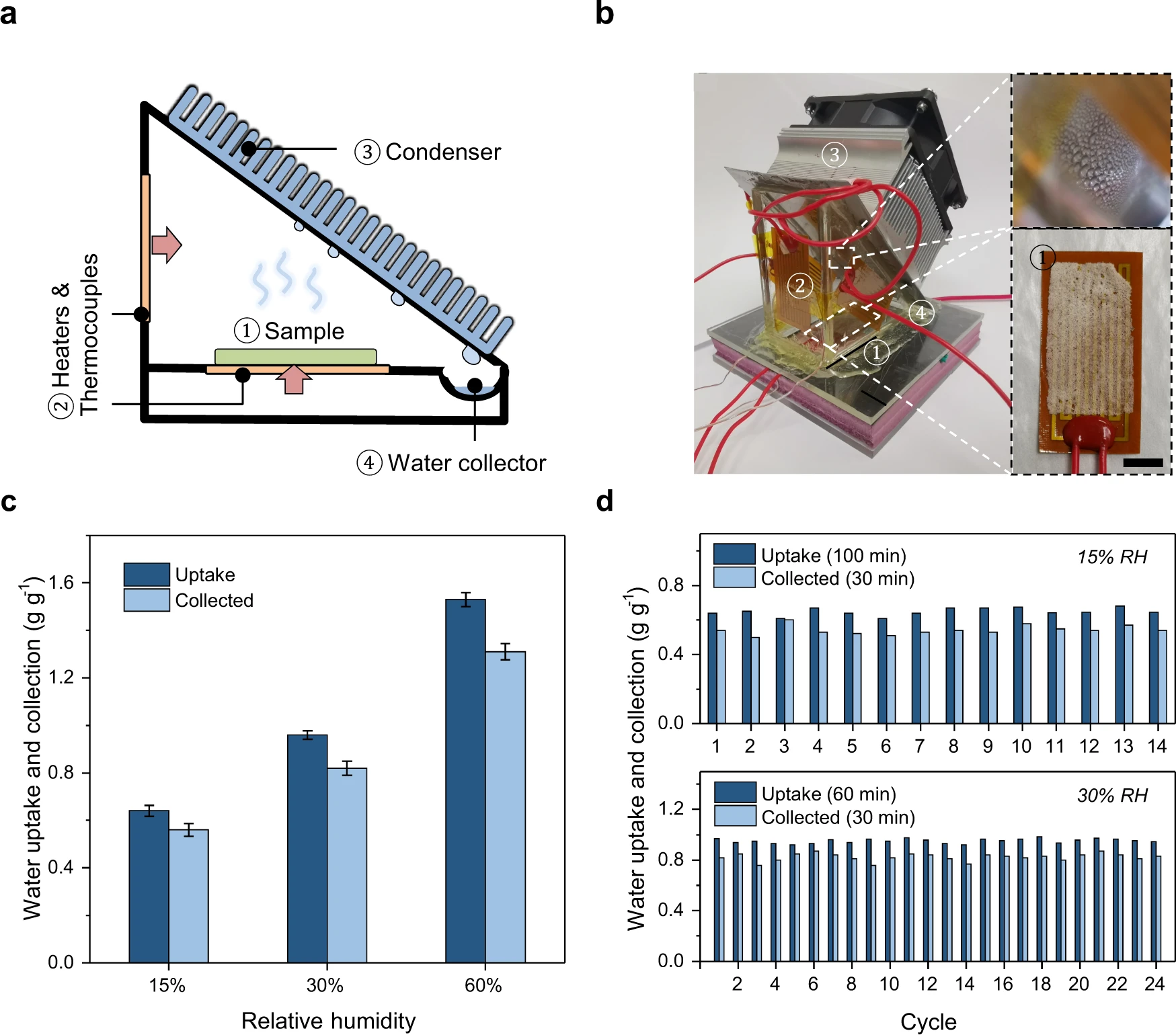

In the test, the gel film can wring an amazing amount of water from the air. When the relative humidity is 30%, each kilogram of gel can produce 13 liters (3.4 gallons) of water per day. Even when the humidity drops to only 15% - which is very low even for desert air - it can still produce more than 6 liters (1.6 gallons) of water per kilogram per day.

Compared with the water collector previously announced by some researchers, this is a huge progress. The previous peak was 8.66 liters (2.3 gallons), but that was in much higher humidity air. Others have a maximum of 5.87 liters (1.55 gallons) or as low as 1.3 liters (0.3 gallons) at 30% humidity.

The team said that the efficiency of the new gel film could be further improved by creating thicker films, absorption beds or other array forms of the material. Perhaps most importantly, the production cost of this material is very low, at only $2 per kilogram. This is another major factor in expanding the scale of the technology and extending it to remote areas and developing countries where it is most needed.

The study was published in nature communications( https://www.nature.com/articles/s41467-022-30505-2 ) 》In the magazine.