Researchers at North Carolina State University have developed a faster and cheaper technology to produce hindered amines, which are used as light stabilizers in products from pharmaceuticals and agricultural chemicals to detergents and organic light-emitting diodes Milad abolhasani, associate professor of chemistry and Biomolecular Engineering at North Carolina State University and corresponding author of the paper on the new technology, said:

"Hindered amines are used in a wide variety of products, but all existing technologies for producing these amines are complex and expensive. We set out to develop a better method for synthesizing these hindered amines, and we succeeded."

A less expensive technology for the production of hindered amines is hydrogen amine methylation, or ham. However, the chemical industry largely avoids the use of ham because there are too many methods that can go wrong - leaving manufacturers with unpopular chemicals rather than the functional amines they are trying to make. Over the years, researchers have improved the ham process. However, all technologies to avoid adverse by-products mean extending the time frame of ham process, so it takes several hours to carry out all necessary reactions. up to now.

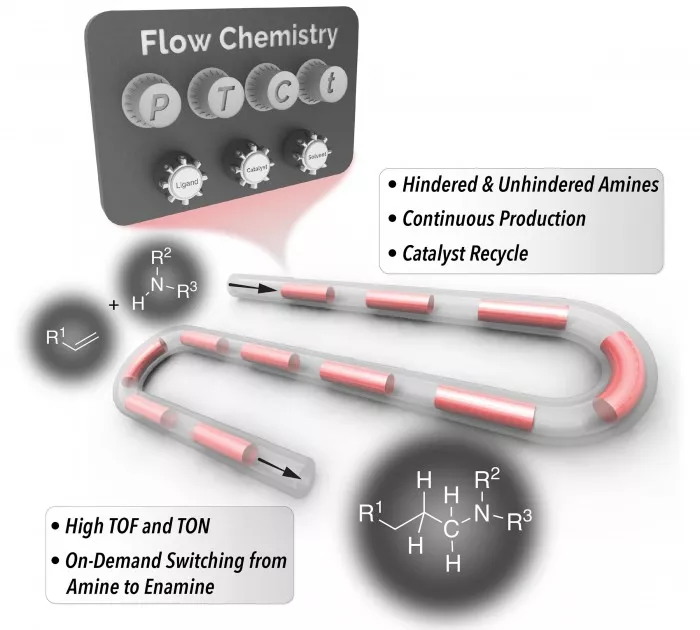

"We have developed a ham technology that uses continuous flow reactor technology to produce hindered amines more effectively," abolhasani said. "Our ham process takes less than 30 minutes in most cases. The only products are hindered amines and water. And we can recover the main catalyst, rhodium / n-xantphos, which further reduces the cost."

The success of this new technology is achieved in two steps. First, by using a continuous flow reactor that allows gas and liquid to flow continuously in the form of segmented flow, researchers can greatly improve the kinetic efficiency of the reaction. Second, the new technology uses an auxiliary catalyst - fluorinated benzoic acid - which reduces the energy required for some necessary reactions in the ham process.

Ultimately, this technology has driven down the cost of using cheap raw materials to produce hindered amines, enabling users to produce hindered amines faster without producing toxic by-products.

"By designing a cooperative catalyst system, we have demonstrated that the rate of hindered amine reaction in our system can be 70 times higher than the most advanced process available," said Malek Ibrahim, the first author of the paper and a former postdoctoral researcher in North Carolina. "This process is also a good example that the mobile chemical platform can improve the turnover frequency of the catalyst, which is becoming more and more important with the rise of the price of rhodium catalyst."

This new technology is particularly attractive for decentralized production and operation, because the necessary equipment covers a small area and is scalable, and users can effectively produce hindered amines on demand on site.

"More importantly, the same technology can also be used to produce aniline on demand -- this is other chemicals -- just adjust the solvent we use in the flow reactor. You can actually switch back and forth between producing amines and olefins without stopping the production process, because the only thing you need to change is the solvent mixture," Ibrahim said

Researchers have applied for a temporary patent for the new technology and are now looking for industrial partners to put the technology into widespread use.

The research paper will be published in the journal Nature communication on May 4, 2022. The work was done with start-up funds from North Carolina.