Cutting down trees and processing wood is not the most effective or environmentally friendly way to make furniture or building materials. MIT has made a breakthrough in this field recently, in the future, wood can be directly 3D printed and planted into the shape of furniture and other objects**

Although wood is renewable energy, its consumption rate has been significantly faster than its growth rate. Deforestation has had a huge impact on wildlife and exacerbated the impact of climate change. Since our demand for wood products cannot change, the way we obtain wood products must also change.

Now, a team of scientists at MIT has demonstrated a new technology that can grow wood like plant materials in the laboratory, allowing easy adjustment of properties such as weight and strength as needed.

Ashley Beckwith, the lead author of the study, said: "our idea is that you can plant these plant materials exactly according to the shape you need, so you don't need to make any subtraction afterwards, which reduces the amount of energy and waste. There is great potential to expand this and grow three-dimensional structures.".

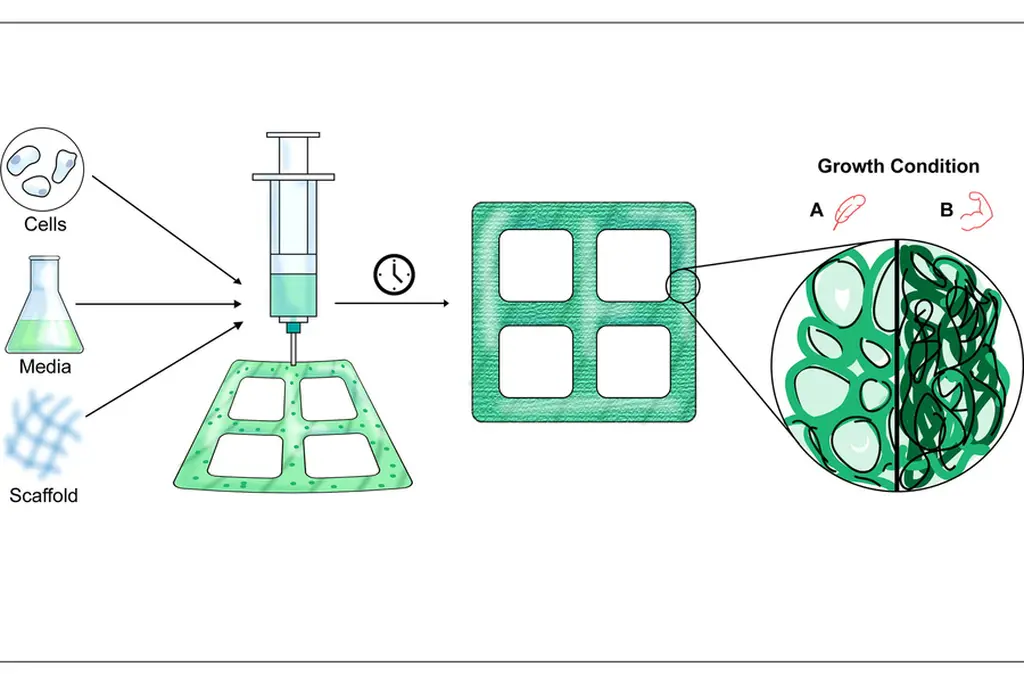

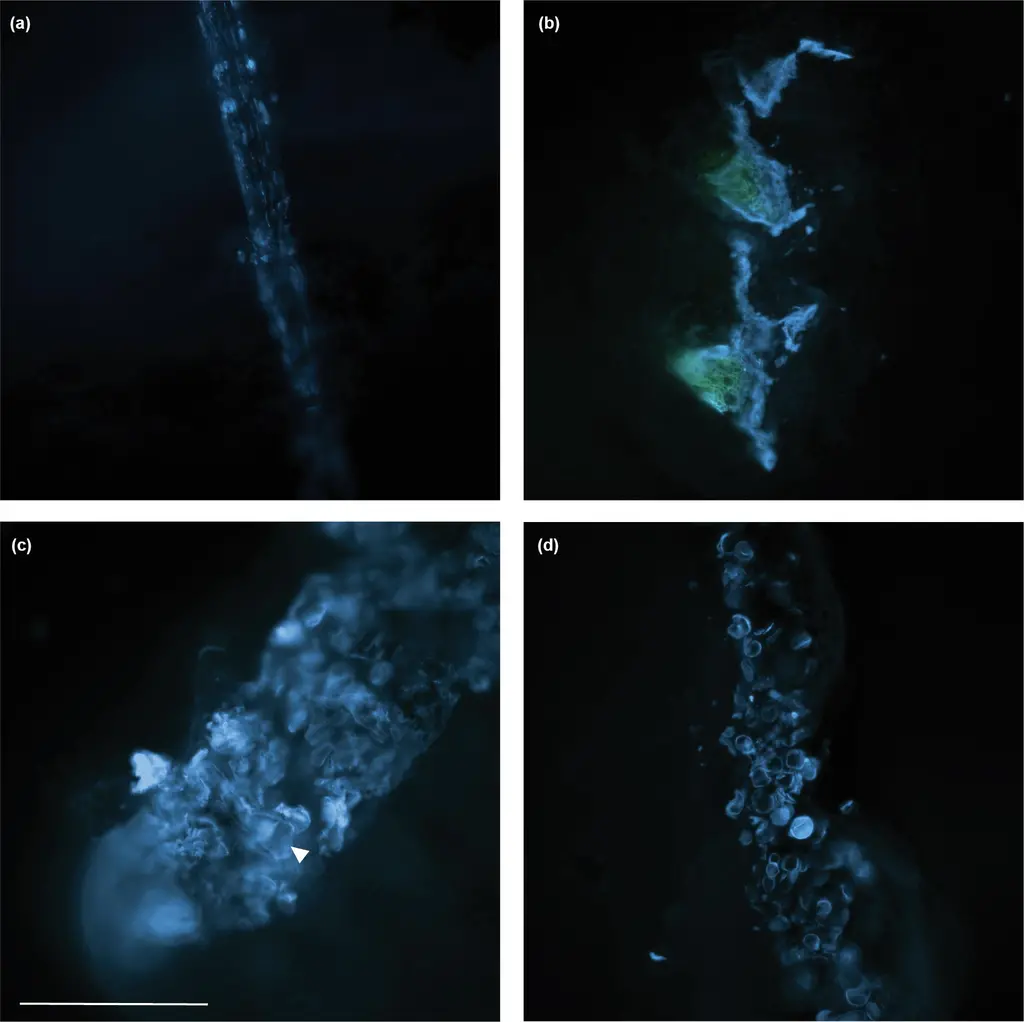

First, the team isolated cells from plant leaves called Zinnia elegans. The cells were then cultured in liquid medium for two days and then transferred to a thicker, gel based medium. This kind of thing contains nutrients and two different plant hormones, and their levels can be adjusted to adjust the physical and mechanical properties of the material.

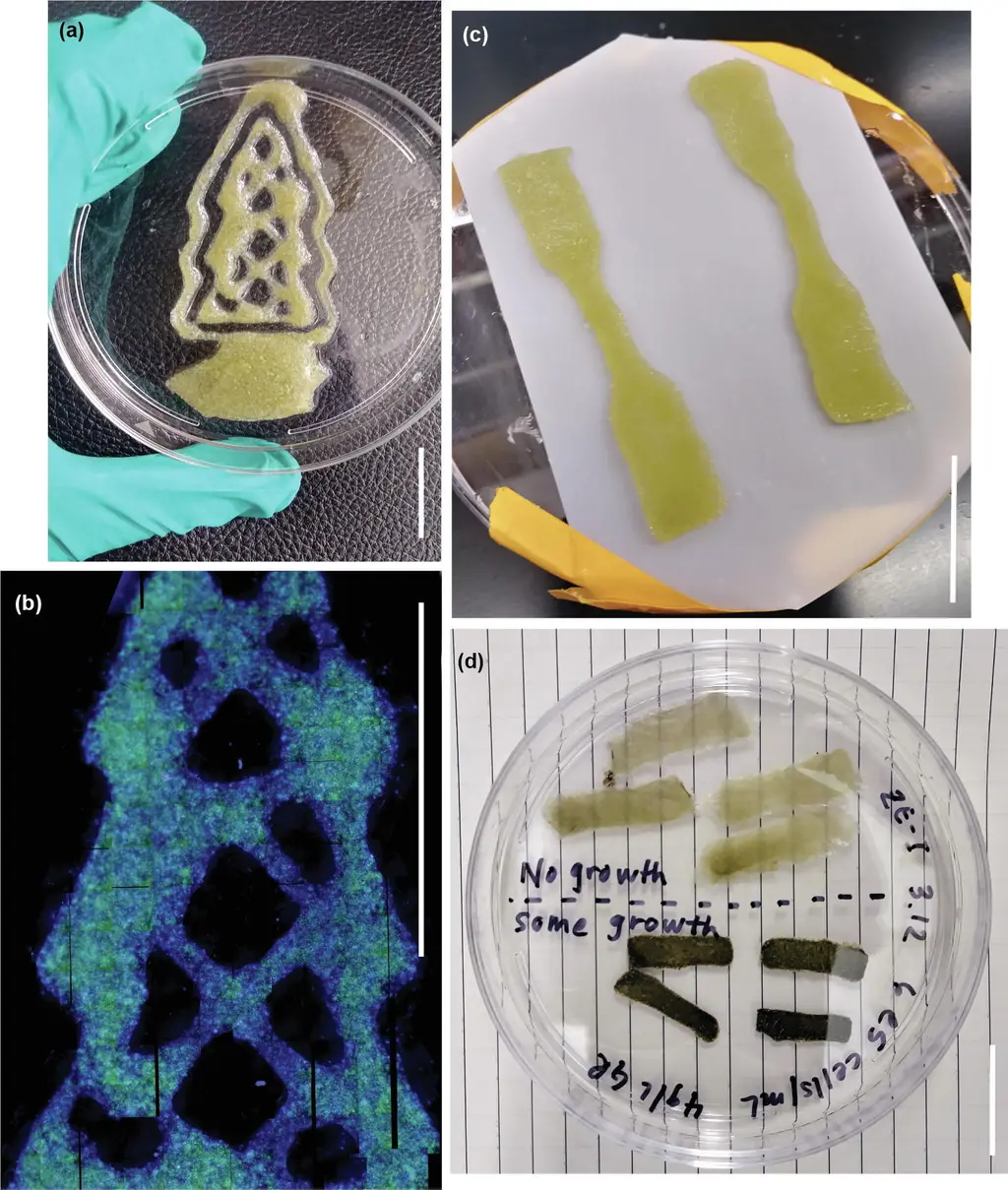

Next, the research team 3D printed the gel containing cells into specific shapes, just like you 3D printed a plastic object. After hatching in the dark for three months, the material is dehydrated, and the final result is a custom object made of wood like plant material. For example, in one test, the team molded the material into a model of a tree.

The team experimented with different levels of hormones and found that lower levels of hormones resulted in lower density materials with round, open cells. At the same time, due to the growth of organic polymer lignin, higher levels will grow smaller, denser structures and harder. This difference can be used to make softer and lighter products, or stronger and harder products.

Ultimately, our goal is to develop this technology so that wooden objects can basically be printed and grown in 3D, rather than cutting, shaping and connecting from larger wood blocks obtained from felling trees. This process may start with small wooden items, such as nails or decorations, and eventually develop into furniture or building boards.