Today's story is a little long, so try to keep it short. As you all know, curved screen mobile phones are difficult to apply film. Therefore, since I changed Xiaomi 11 last year, I have been using the film from the factory. Even if it has more and more scratches, I haven't moved the idea of changing the film. However, just a while ago, seeing that the film had begun to tilt, which affected the feel of my sideslip return, I planned to paste the film again.

Considering that almost all domestic mobile phone manufacturers generally provide free film service, I think I'll go to the after-sales service point one day and ask the staff there to change one for me.

However, when I really went all the way to the service point.

People over there told me that the curved screen mobile phone can really enjoy the free film, but the film applied for this month has been used up. If you want to apply the film, you have to wait until the film arrives at the beginning of next month...

Come on, I'd better find a repair shop on the roadside to apply the film.

However, when asked about the price, good guy, the soft film starts directly at 80, and the toughened film is 120 . Sticking three films is enough to change an external screen for the mobile phone. The price persuaded me to retreat. I thought I could do it for 20 or 30 yuan.

But before I left, a machine in the store caught my attention.

After checking back, I found out that the original reason why the repair shop can film so many mobile phones is not because they have prepared each type of film, but because there is such a kind of machine that can cut a whole film into various sizes**

This kind of machine is not cheap. The price is generally more than 1000 to 2000. But when I think of this machine, I can not only film my mobile phone, but also set up a stall to film others.

The cost of a film is more than one yuan. I only earn 30 yuan for each film. As long as I paste 60 films, I can get back the capital. Next, I earn it!

So I spent a lot of money on a film cutting machine and a film sticking artifact

What is the purpose of this blue film artifact with simple design and only two control buttons up and down? I'll tell you later.

Let's take a look at this film cutting machine with its own touch screen and high technical content.

This film cutting machine is a small machine tool. Its working principle is to roll the mobile phone film to the console through the roller, then control the cutter head to cut the film into specific dimensions, and finally roll out the film.

The poor friends may not understand this before, next, let's actually show you the whole process of coating curved screen mobile phones with this machine**

The first step to film the mobile phone is to select the corresponding model on the touch screen.

The main function of this touch screen on the film cutting machine is to select models. It has to be said that it supports quite a lot of models. Basically, all mainstream models are covered, and even many discontinued brands are not left out:

Besides the front film, you can even choose to cut the film into back film, frame film or lens film:

After selecting the model on the screen, the next step is to put the film in and adjust the scale of the cutter head.

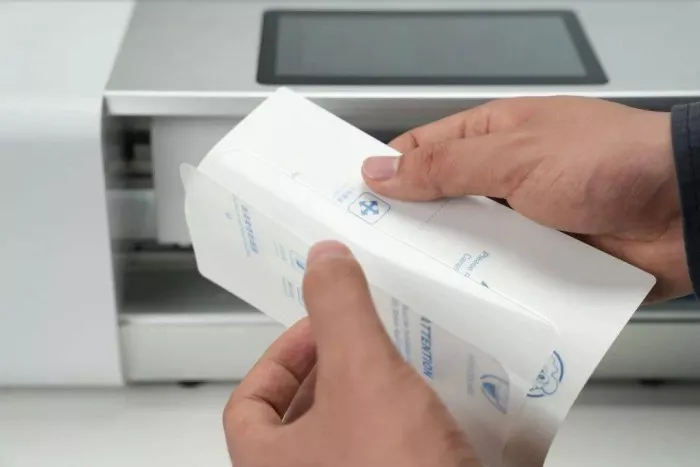

The step of putting film is very simple. Just put a whole film on the console and gently push it in. As soon as the film cutter detects that there is a mobile phone film approaching, it will turn the roller to roll the film onto the console:

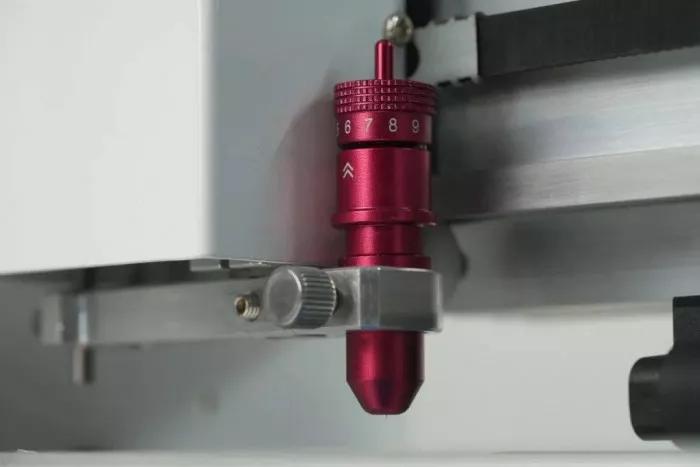

The reason to adjust the scale of the cutter head is that there are many kinds of films that can be cut by the film cutting machine. In addition to the conventional water condensation film, it can also cut the explosion-proof film. The specific depth of the cutter head needs to be controlled by adjusting the scale**

For example, if I cut an ordinary water condensation film, I just need to adjust the scale to 5 or 6. If it is a thicker explosion-proof film, I need to adjust the scale to 7 or 8. The larger the scale is, the more convex the cutter head is, and the deeper the cutting is.

I bought two kinds of membranes, namely high water condensation membrane and high-definition explosion-proof membrane.

According to my observation, although the explosion-proof membrane feels bare metal, it is very easy to produce scratches, and it is not generally difficult to stick the explosion-proof membrane. If you are not careful, several bubbles will be left on the screen;

Although the hydrogel membrane is not easy to leave scratches, it feels a little astringent, and the hand feel is not as good as the explosion-proof membrane. However, it is very easy to stick it, I still choose the hydrogel membrane here.

When everything is ready, click start and the film cutter will start cutting.

By default, it will cut holes in the position of the speaker and front camera. If you don't want to cut holes, you can only shut down the machine halfway. After cutting, the roller will automatically push out the film.

Generally speaking, as long as the scale of the cutter head is set correctly, the cut mobile phone film can be easily removed from a whole film**

To be honest, the previous steps are quite simple. You can operate them as long as you are familiar with them. the next film pasting link is the job to test the technology**

The removed film is divided into three layers. The bottom layer and the top layer will be removed at that time. Only the middle layer is the film that really needs to be pasted on the mobile phone screen.

If you look closely, you will find that the bottom layer of film is sticky and divided into two sections.

On the one hand, this design is to facilitate us to align the film with the screen to prevent the film from sliding away. On the other hand, it is also to reduce the generation of bubbles by pasting the upper half of the screen first and then the lower half of the screen to shorten the stroke:

It can be said that the most difficult step in the film pasting process is to aim at the screen and prevent bubbles. As long as you control the force and paste it several times, you should be able to master the skills.

In addition, since the film pushing tool itself is flat, it is used to paste the curved screen. The film cannot cover the curved surfaces on both sides, at this time, it is the turn of the film pasting artifact**

This thing can use compressed air to drive the film above to press the mobile phone screen in an all-round way, so that the film can be completely adsorbed on the curved surface. Of course, if there is no film artifact, you can press it by hand.

OK, the above is the whole process of mobile phone film pasting. The film of the following mobile phone is pasted by using this film cutting machine with film artifact and my exquisite film pasting technology. It is perfect~

I think I can make money by setting up a stall with this tool and craft.

If there are bad friends who want to know whether I can get back the money and how much money I will make when I set up a stall, welcome to station B to pay attention to a wave of bad comment TV. The later plot will be presented in the form of video at that time. Thank you for watching!