Recently, the reporter learned from the Shenzhen Institute of advanced technology of the Chinese Academy of Sciences that tangyongbing, a researcher of the Institute, has developed a new type of aluminum based composite anode material, which makes lithium batteries withstand the hot climate, the ice and snow, the rapid charging and the cost reduction At present, this achievement has been used in large-scale mass production.

◎ diaowenhui our reporter liuchuanshu

Due to the limitations of key battery materials, one of the major limitations of lithium-ion batteries at present is that they cannot be recharged at low temperatures below zero, while their safety cannot be guaranteed at high temperatures above 50 ℃. China has a vast territory, and the temperature varies greatly with regions and seasons. The temperature in winter in the north can be as low as -40 ℃, while the surface temperature in summer in the South can be as high as more than 50 ℃. In winter, electric vehicles cannot be started, smart phones automatically shut down, and spontaneous combustion of electric vehicles in summer occur from time to time.

At present, the technologies related to cathode materials of batteries are close to the "ceiling". To improve the performance, there is still room for development of cathode materials. For this reason, the team has developed a new aluminum based composite cathode material over the years. By matching with the cathode material of commercial lithium-ion batteries, the team has successfully developed new lithium manganate, lithium iron phosphate, ternary batteries and other products for different application scenarios. The new lithium-ion battery using this material has a minimum operating temperature of -70 ℃ and a maximum operating temperature of 80 ℃, and its low-temperature and high-temperature performance can be taken into account at the same time.

In terms of safety performance, with the continuous use of conventional lithium batteries, lithium dendrites will be generated inside, which will not only affect the charging capacity, but also may puncture the diaphragm, resulting in hidden dangers such as battery short circuit. The new aluminum matrix composite cathode material developed by the team can effectively alleviate the generation of lithium dendrites under low temperature and overcharge conditions, and improve the safety of the battery.

In terms of endurance performance, thanks to the high theoretical capacity of aluminum based composite anode material, the energy density of the battery is 13% - 25% higher than that of traditional lithium-ion battery, which can achieve long endurance. In addition, due to the excellent conductivity of aluminum based composite negative electrode material, the product also shows good fast charging performance. It can be fully charged in 20 minutes.

In terms of cost, based on the performance advantages of aluminum matrix composite cathode materials, combined with the high-performance electrolyte developed by the research team, low-temperature battery products can get rid of the dependence on expensive nano cathode materials. Because the current low-temperature battery cathode needs nano materials, the cost is relatively high. The aluminum matrix composite cathode material developed by the research team eliminates the need for the cathode material to be nano-sized. In terms of reducing the material cost, the battery cost can be reduced by 10% - 30%.

"Some scenarios require the battery to be able to charge and discharge normally at -40 ℃, while some scenarios put forward higher requirements for the battery in terms of long cycle. In combination with the actual situation, we constantly make adjustments to the product." The team said that the relevant products can be applied to photovoltaic energy storage, home energy storage, communication base station energy storage, rail transit, national defense construction, aerospace, polar scientific research and other fields, especially in alpine and subtropical regions, significantly expanding the application range of batteries.

At present, the project is in the process of capital and share increase negotiation. It will further build a large-scale production line of new batteries and quickly promote the application of new battery products in many fields.

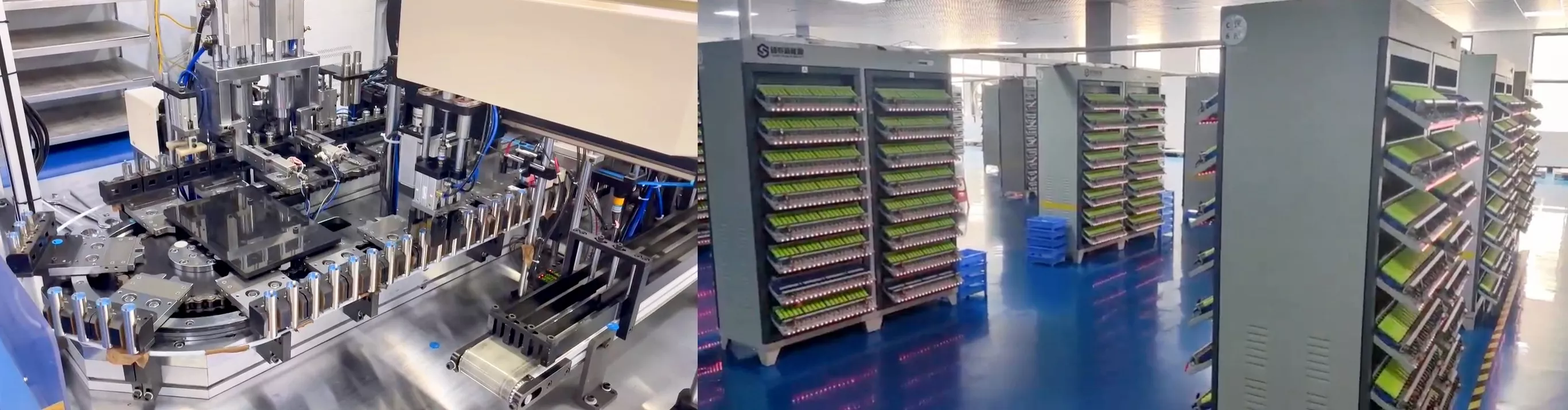

Local (left) and batch test of new battery large-scale production line (right)

High and low temperature performance test of new battery (left: -70 ℃ test, right: 80 ℃)