If we want to curb the waste problem, we need to creatively recycle and reuse materials. In a new study, researchers from Rice University and Ford research and Innovation Center showed how to use the waste plastics of old cars to make graphene foam, which can then be used in new cars**

This research has promoted a technology called "Joule thermal flash". Rice University's team demonstrated for the first time in 2020 the production of graphene from waste materials such as food residues, plastics and old tires. These wastes are ground into powder and then heated to 2027 ℃ to 2727 ℃ by high voltage electricity. This will enable the carbon in the material to be quickly converted into graphene sheets, while other elements are evaporated into gas, which can be collected and used in other industrial processes.

This is not only a cheaper way to make graphene, but it requires much less energy and gets rid of the materials that are usually landfilled or incinerated. In the new study, Rice University scientists showed a new way in which this cycle can work in the real world.

After seeing the original paper, Ford researchers contacted the James tour laboratory at Rice University to test whether the technology could be used to recycle the mixed plastic waste of end-of-life vehicles. So the car company sent 4.5 kilograms of broken plastic from the bumpers, washers, carpets, cushions, seats, etc. of the old F-150 pickup truck. Importantly, these plastics do not even need to be classified first.

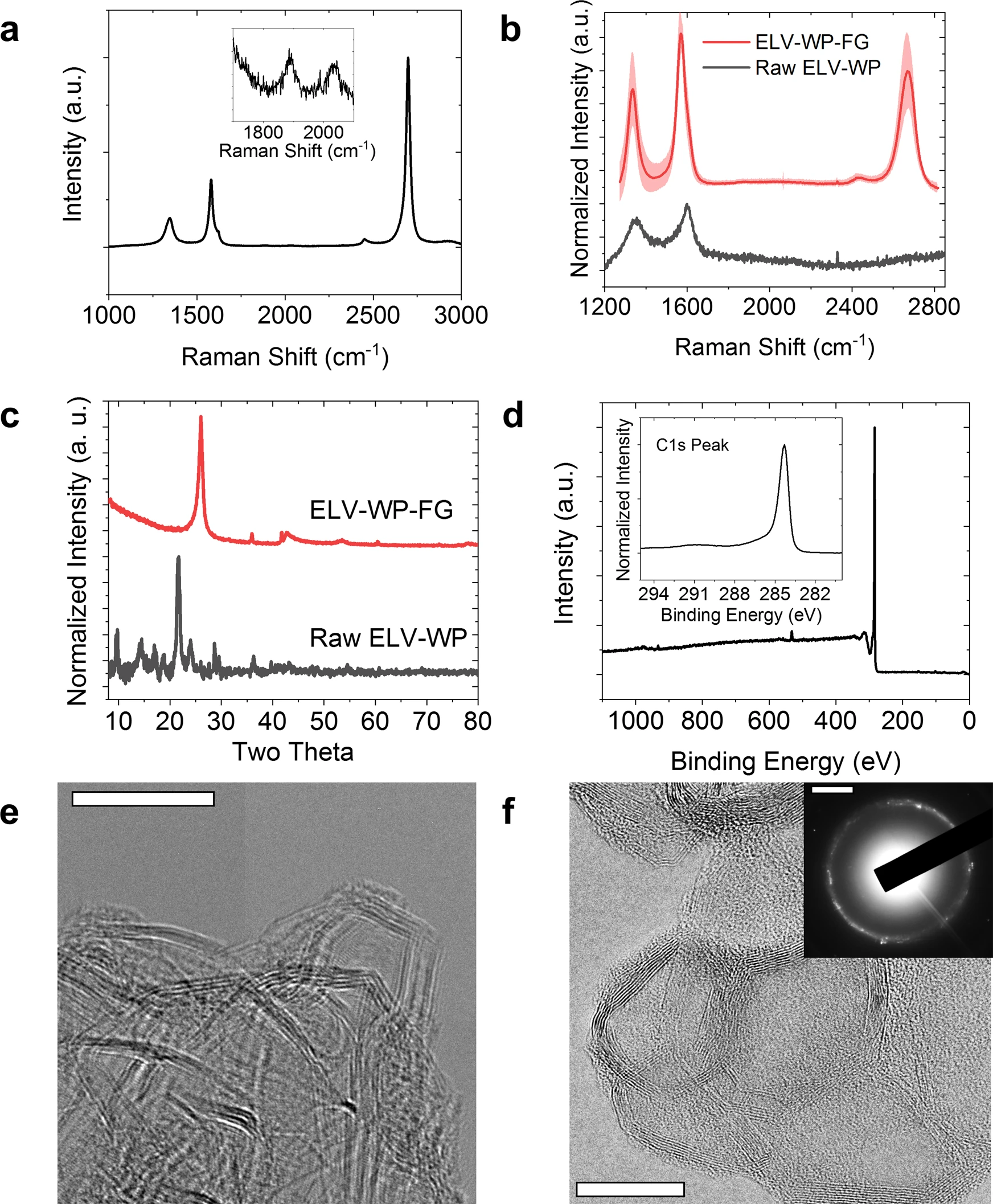

Rice's team first ground the material into fine powder, and then flashed it in two steps. First, it is heated with a low current for 10 to 16 seconds to form a highly carbonized plastic material. Only 30% of the original blocks are still solid, and most of them will deflate or form hydrocarbon rich waxes and oils, which the team says can also become useful industrial materials.

Next, the carbonized plastic is flashed with high current to convert 85% of the plastic into graphene. The rest is discharged in the form of hydrogen, oxygen, chlorine, silicon and trace metals.

The resulting graphene can be used in many applications expected of this magical material. In this case, the rice team sent it back to the Ford team. The Ford team used it to strengthen their polyurethane foam, which was used to isolate the noise and vibration of the vehicle. As the weight of graphene is only 0.1%, the tensile strength of the new foam is increased by 34% and the absorption of low-frequency sound is also increased by 25%.

To really prove the potential of recycling, samples of this foam were then sent back to Rice University, where the researchers showed that it could also be flashed into new graphene. This shows that this method is really useful in the real world and brings new life to waste materials.

The study was published in [Communication Engineering] under nature( https://www.nature.com/articles/s44172-022-00006-7 ) 》In magazines.