Compounds that form tiny crystals hold secrets that could accelerate renewable energy production and the development of semiconductors. The discovery of its atomic arrangement has led to advances in material research and solar cells. However, existing techniques for determining these structures may cause damage to fragile microcrystals.

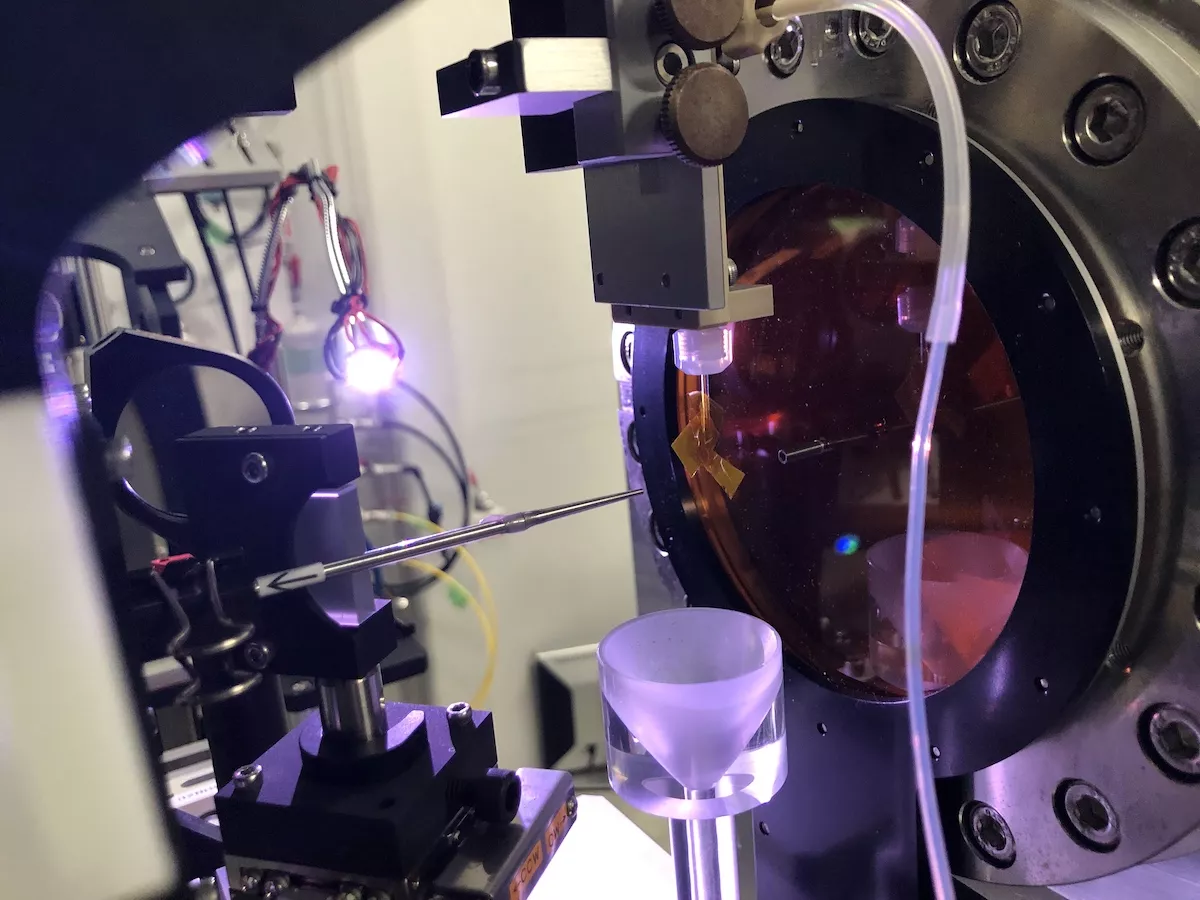

Now, scientists have a new tool in their tool belt: a system for investigating thousands of micro crystals with ultrafast pulses from an X-ray free electron laser (xfel), which can collect structural information before damage occurs. This method has been developed in the past decade to study proteins and other large biomolecules at the SLAC National Accelerator Laboratory of the Ministry of energy. It is now applied to small molecules of interest in chemistry and materials science for the first time.

Researchers from the University of Connecticut, SLAC, Lawrence Berkeley National Laboratory of the Department of energy and other institutions have developed a new process called small molecule series femtosecond X-ray crystallography (smsfx), which can be used to determine the structure of three compounds that form microcrystalline powder - including two previously unknown compounds.

In a paper published in nature on January 19, the research team wrote that since this new method should be "widely applicable to xfel and synchrotron radiation facilities equipped with serial crystallography, it may have a great impact.

Release metal compounds

Researchers used this method for the first time to determine the structure of two metal organic materials, thiorene and tethrene. Both materials are potential candidates for the next generation of field effect transistors, energy storage devices, solar cells and panels. Drawing thiorene and tethrene maps enables researchers to better understand the reason why some other metal organic materials emit bright blue light under ultraviolet light. Scientists compare it to Frodo's magic sword sting in the Lord of the rings.

"Determining the crystal structure of materials is the starting point for implementing them into equipment and considering engineering applications," said Elyse schriber, a researcher from the University of Connecticut and co-author of the paper.

Nicholas Sauter, a computer scientist at Berkeley Laboratory, pointed out that, however, many materials refuse to be formed into large crystals required for standard X-ray crystallography. "Instead, most substances form powders, and their X-ray diffraction patterns are more difficult to unravel."

Mike Dunne, director of LCLs, said that using smsfx to solve the crystal structure can accelerate the modeling of other microcrystalline structures and lead to the discovery of new materials for molecular machines, wear mechanisms of batteries and fuels. "This is an exciting study that takes LCLs in a new direction. This type of cross science uses advances in bioscience to enter other fields, such as advanced materials science, which is a good example of how our DOE user facilities combine different areas of the research community."

Schriber said that each new crystal structure is uploaded to the global crystallography database hosted by the University of Cambridge, which scientists can use to test theories and help find compounds useful for specific tasks. She said that in other crystal mapping methods, researchers usually select the best crystal in a group of crystals for modeling, and by using smsfx, they can get a more comprehensive view of the whole crystal group, "so it is a better model of material appearance".

"Duck sauce "**

The experiment didn't go exactly as planned, but a little creativity saved it all. In xfel series crystallographic investigation, microcrystals must be transported to the X-ray beam through a liquid sample transportation system. The researchers tried to transport the crystallite with methanol, but found that it was incompatible with the epoxy resin on the nozzle through which the liquid sample flowed. In some cases, it melts the nozzle.

What makes them feel stressed is that they know they can't transport their microcrystals with water because their crystals have waxy organic components that make them hydrophobic. Water can clog the system and cause crystals to stick to both sides of the delivery system pipes.

At a loss, the team remembered that dishwashing agent had been used to remedy the oil spill. They quickly searched and found a bottle of detergent and mixed it with water. They called the combination "duck sauce" and sent the mixture into the conveying system.

"I never thought in my life that I would sing praises for detergent, but it's a magical pendant for our materials. If we didn't use a detergent water mixture, we wouldn't be able to complete our experiment at all," schriber said.

The future of fragile crystals

As for the next step, the researchers hope to map the crystal structure of a large number of materials, because "any one of them may have incredible properties that we don't know," schriber said. "Suddenly there is a structure, there is an opportunity to predict the properties of many other materials."

The research team also said that the xfel smsfx process may become faster and find a large number of unknown crystal structures, and they are trying to simplify the method.