A team of engineers at the Federal Institute of Technology (EPFL) in Lausanne, Switzerland, has developed a 3D printing method that uses light to turn opaque resins into objects in seconds This breakthrough may have good application prospects in the biomedical industry, for example, it can be used to manufacture artificial arteries. The study was recently published in the journal advanced science.

As early as 2017, engineers from the applied photonic device laboratory (LAPD) of the EPFL School of Engineering designed a 3D printer that can produce objects almost instantaneously. Five years later, the team improved their printing equipment and methods to produce items made of opaque resin, which could not be achieved before.

EPFL's 3D printer is one of the fastest printers in the world. Most 3D printers work by depositing materials layer by layer, a process called additive manufacturing. EPFL uses the volumetric method, that is, the resin is poured into the container and rotated. Engineers illuminate the container with light from different angles, so that when the energy accumulated in the resin exceeds a given level, it will solidify. This is a very precise method, which can make articles with the same resolution as the existing 3D printing technology.

This volume method can be used for almost any shape of object. It took engineers only 20 seconds to make the tiny statue of Yoda in Star Wars, while the traditional manufacturing process took about 10 minutes.

Light can cure the resin by interacting with photosensitive compounds contained in the plastic. Engineers said that the new method is only effective when light passes through the resin in a straight line without deviation, while light in opaque resin cannot travel smoothly. To this end, they designed a solution.

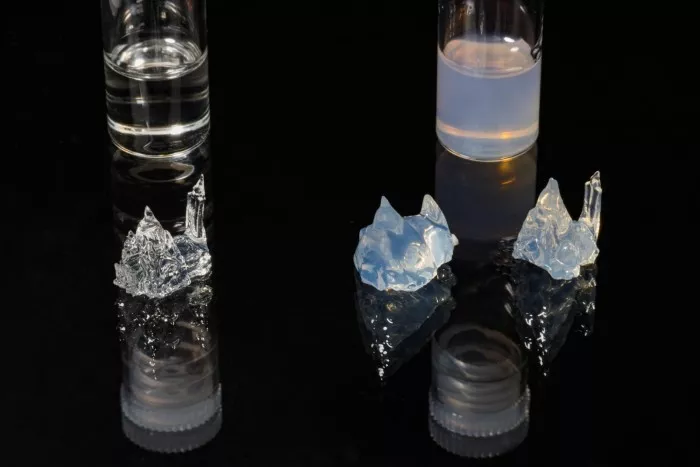

First, they used a camera to observe the path of light through the resin, and then adjusted the calculation to compensate for light distortion. They also programmed the printer to run calculations and correct the light, which ensured that the machine could reach the energy required to cure the resin in time. As a result, engineers can print objects in opaque resin with almost the same accuracy as transparent resin, which is a major breakthrough.

Next, engineers hope to use new methods to print several materials at the same time and improve the resolution of the printer from one tenth of a millimeter to microns. (trainee reporter Zhang Jiaxin)